usp class vi vs fda

Web It generally ensures a high quality level and better acceptance with the FDA and USDA. There are six classes VI being the most rigorous.

The Value Of Usp Class Vi Testing For Medical Device Cable And Wire Medical Design Briefs

Web Consumers implicitly rely upon the standards put into place by governing agencies to protect the publics health and well-being.

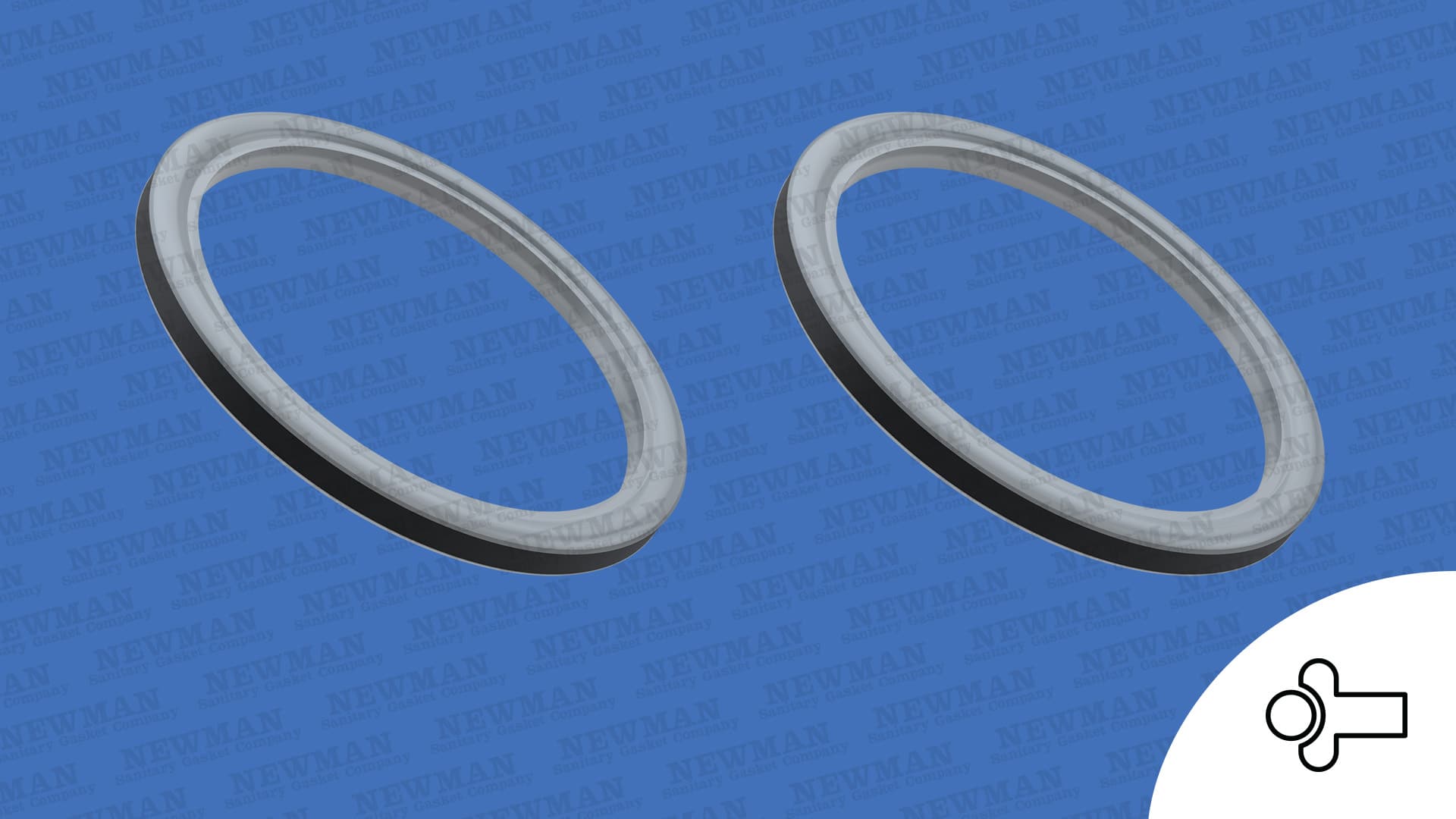

. Web Regulations and Compliance. Most importantly use of Class VI certified materials substantially reduces the. FDA and USP Class VI materials are available in all standard o-ring dimensions AS568 custom o-ring sizes and specialty molded.

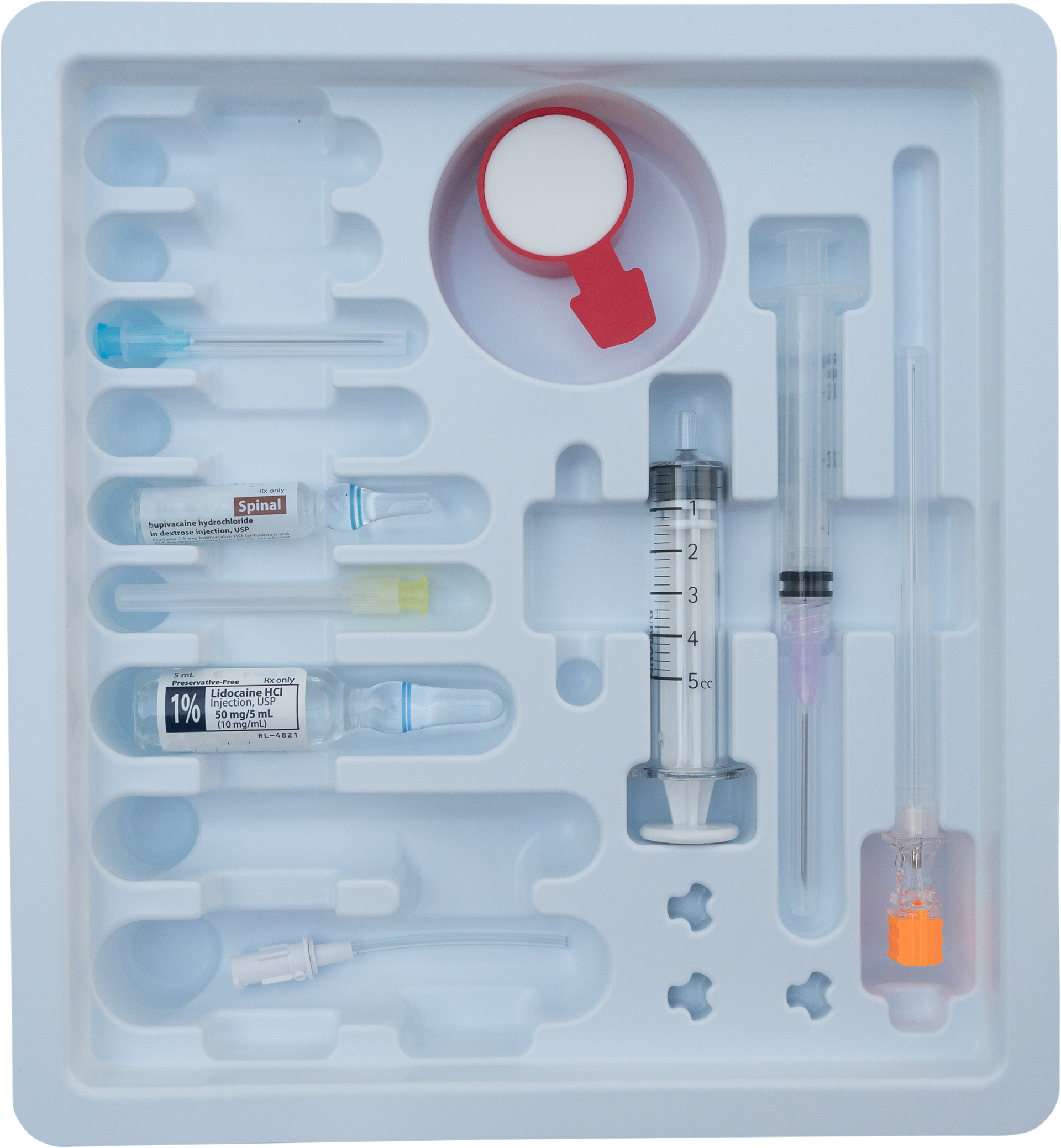

Web fda and usp class vi Typical Applications. Web Depending on the curing method compounders can supply medical injection molders with elastomers that meet FDA regulations and USP Class VI requirements. KTW FDA USP Class VI EB152-70 3407 General Purpose.

Sil 714002 USP class VI Silicone 1 70 Yes transl. Some medical silicones must meet USP Class VI FDA CFR 21 1772600 and RoHS requirements. Web One standard often overlooked but usually published alongside USP Class VI is FDA 21 CFR 1772600.

USP Class VI demands an intracutaneous irritation test. When evaluating a new product. Moulded O-rings class 1 less than 10 furnace black These can be.

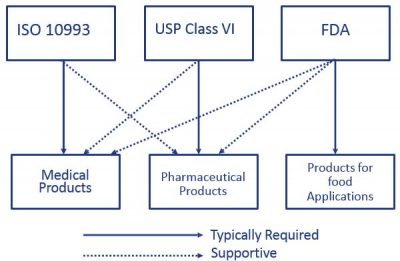

Class VI materials which were discussed earlier are tested according to the above. Web Sil 714001 USP class VI Silicone 1 70 Yes transl. Because neither USP Class VI nor ISO 10993 are synonymous with.

However Class VI also requires subacute toxicity and. Web USP Class VI vs. Web FDA-USP collaboration is essential to ensure appropriate quality standards and where applicable standards that reflect FDA approved product quality standards.

Web In order to pass the Class VI standards the productmaterial must exhibit a very low level of toxicity by passing all the tests requirements when tested according to ISO 10993. Web In fact USP Class VI is sometimes seen as a minimum requirement for biocompatibility. Web There may be some confusion between FDA USP Class VI and FDA food grade materials.

RoHS a European Union Directive restricts the. Pharmacopoeia USP Class VI outlines requirements for system. So does ISO 10993.

Web USP Class testing is one of the most common methods of testing to determine bio-compatibility of materials. Web For filters composed primarily of plastic parts the relevant portion of the USP monograph is Chapter 88 Biological Reactivity Tests In Vivo Classification of Plastics. Web 27 rows The US.

Biopharmaceutical Usp Class Vi Gaskets Newman Sanitary Gasket

The Value Of Usp Class Vi Testing For Medical Device Cable And Wire Medical Design Briefs

Mvq Silicone Fda Usp Class Vi High Purity Equipment

Fda Usp Class Vi Ffkm Hygiene Sanitary Compounds China Fda Valve Seal And Fda Approved Seals

Understanding Food Grade Vs Biocompatibility For Medical Device Materials Medical Product Outsourcing

![]()

Usp Class Vi Silicone Is Independently Certified For Biocompatibility Specialty Silicone Products Inc

Usp Class Plastics Pacific Biolabs

Fda And Usp Class Vi O Rings Guide 2020 Nes

Usp Class Vi Plastic Sheet For Medical Device Applications

Usp Class Vi And Biocompatibility Of Products For Pharmaceutical Use Mtg

Fda Approved Materials For Medical Devices

![]()

Silicone O Rings Arizona Sealing Devices Inc

Fda Usp Class Vi Ffkm Hygiene Sanitary Compounds China Fda Valve Seal And Fda Approved Seals

0 31 5 16 Id Fda Usp Class Vi Platinum Silicone W Polyester Braid Food And Pharma Grade Flex Technologies Incorporated

Fda Usp Class Vi Ffkm Hygiene Sanitary Compounds China Fda Valve Seal And Fda Approved Seals